Food

The issue:

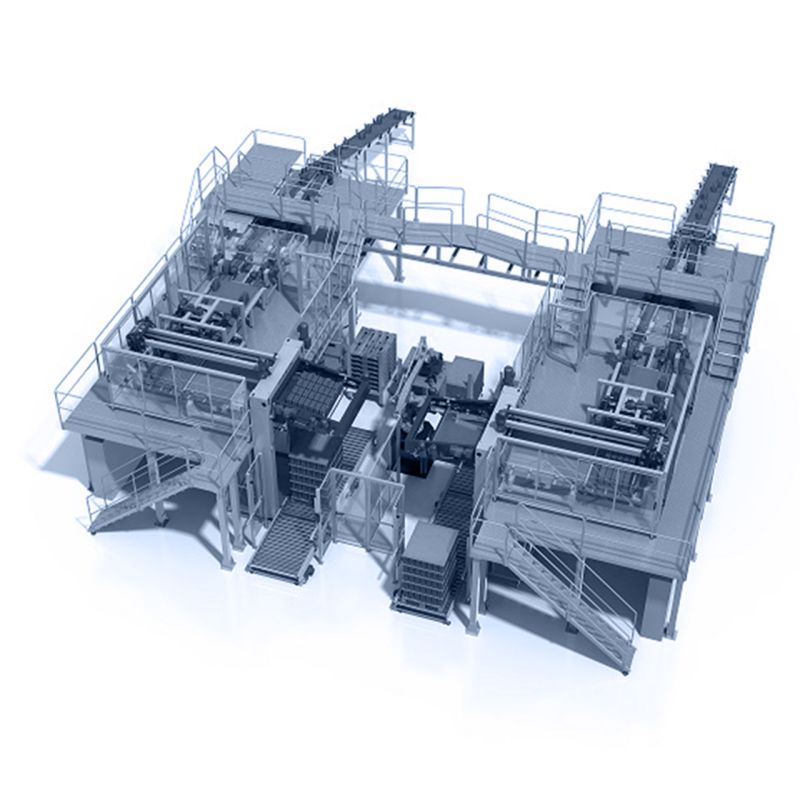

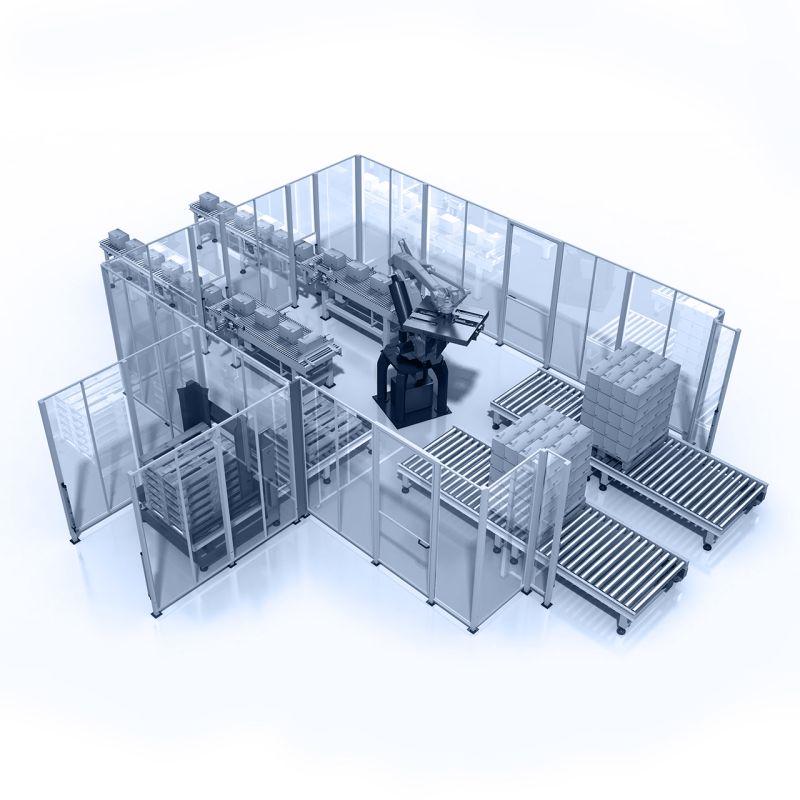

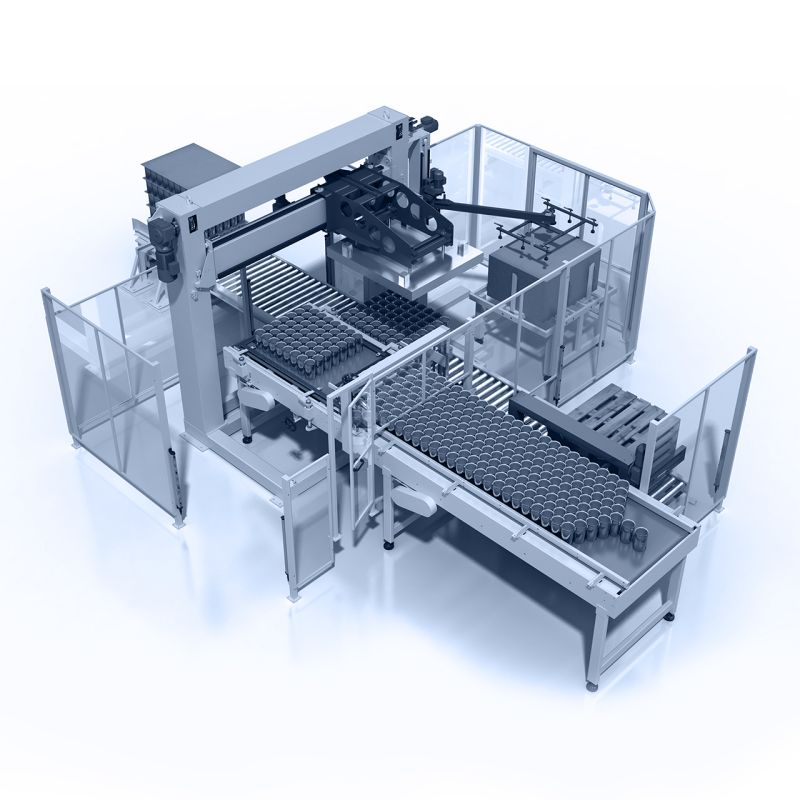

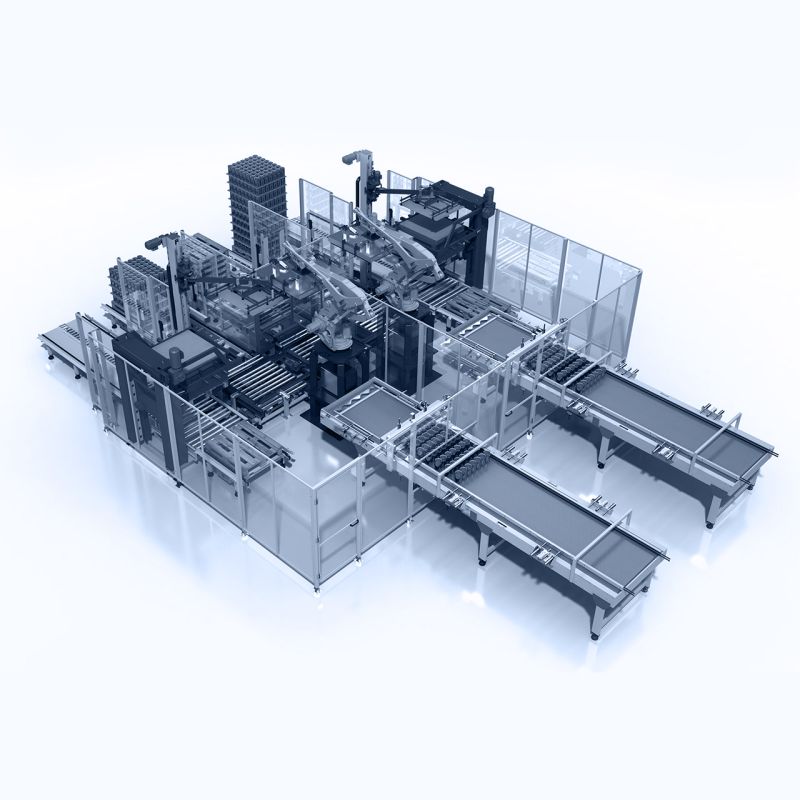

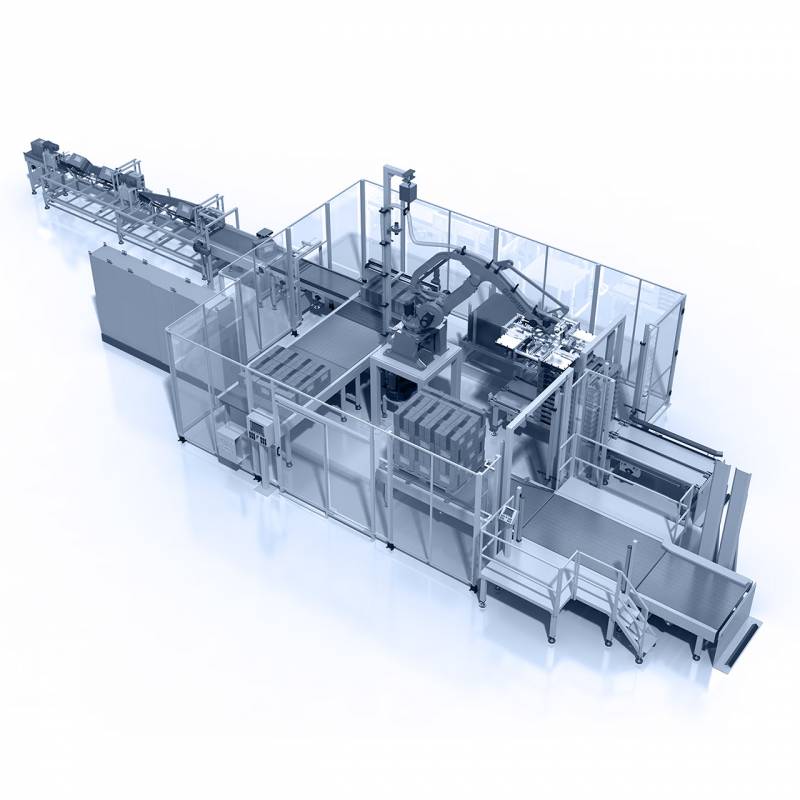

the customer required a complete front & end of line solution for ketchup bottle with performances of 600 bottles/min. For the customer this production line is the most important in terms of consumer product.

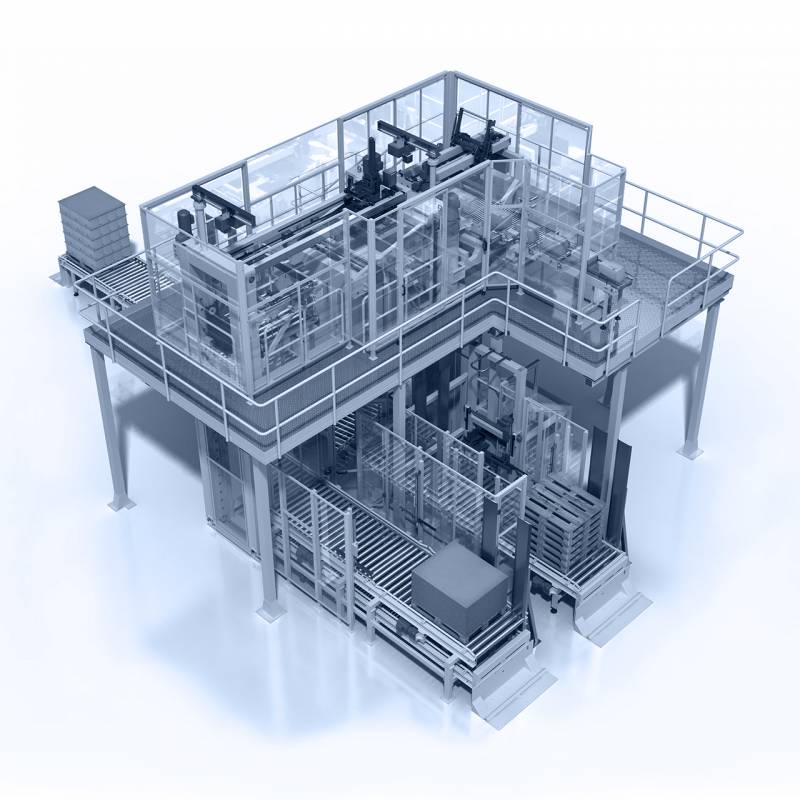

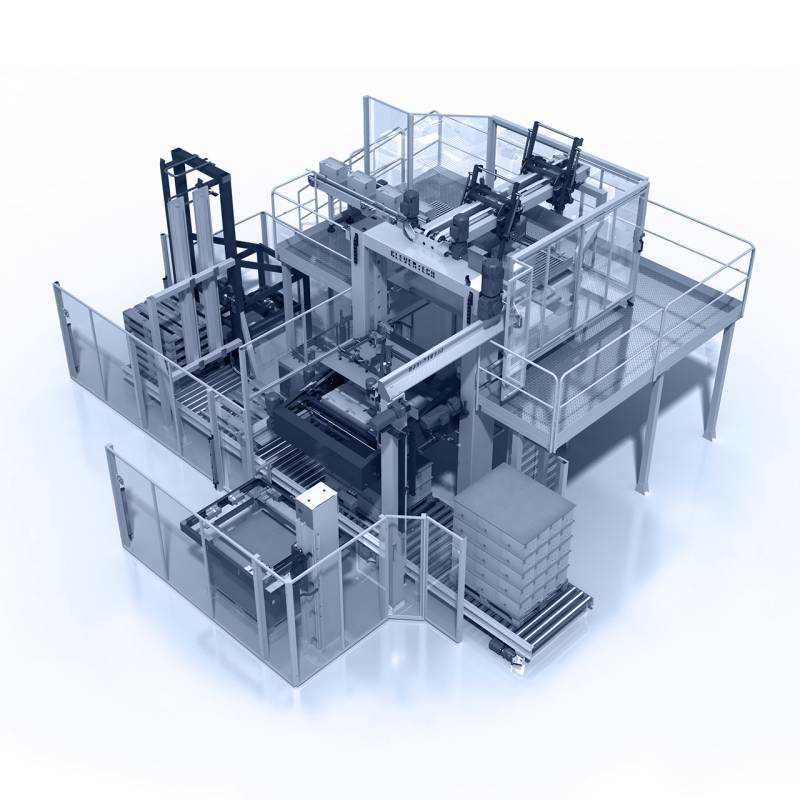

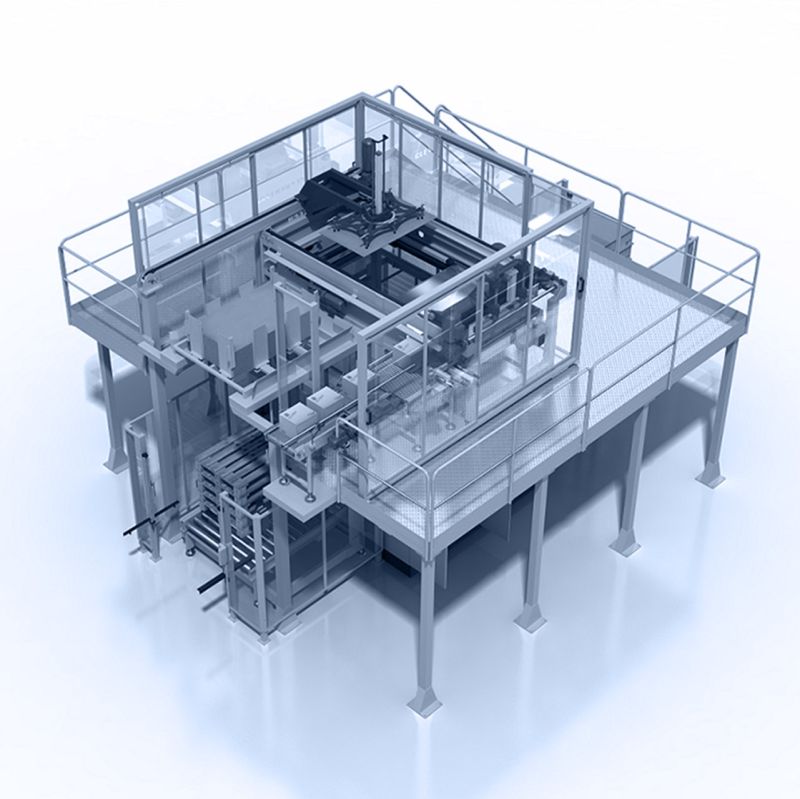

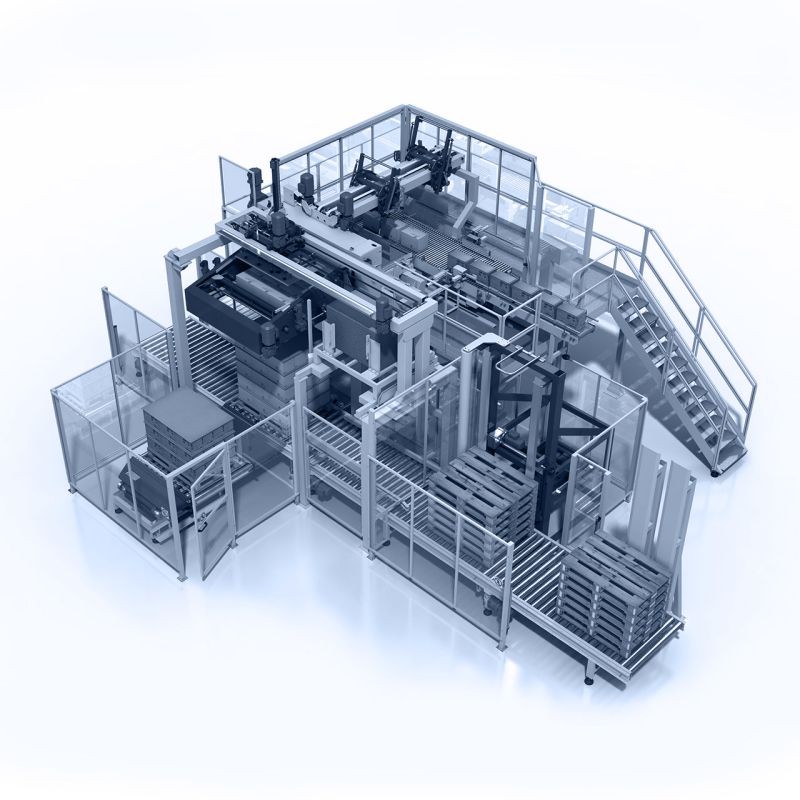

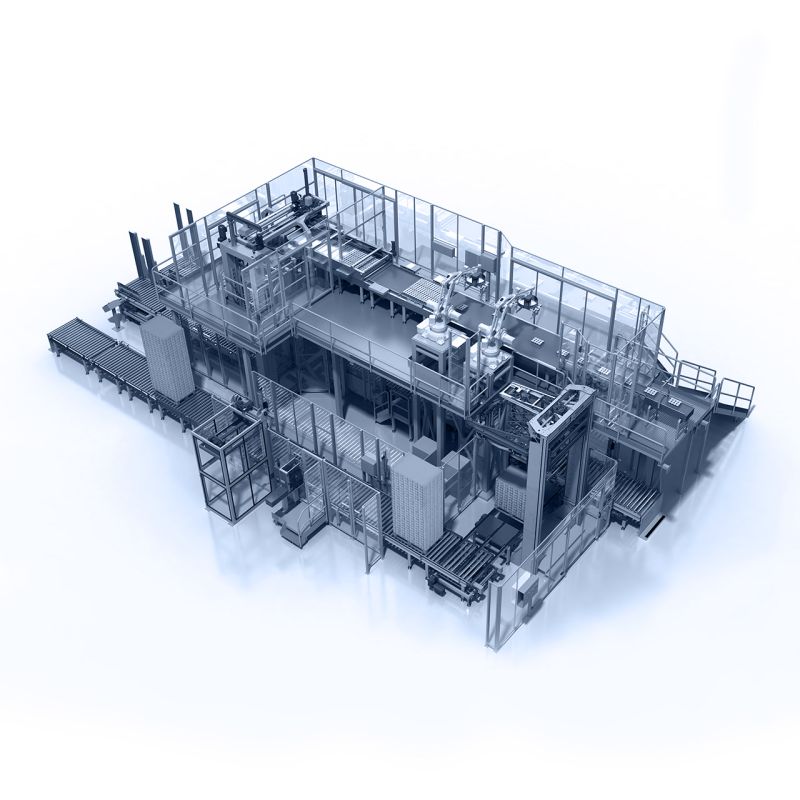

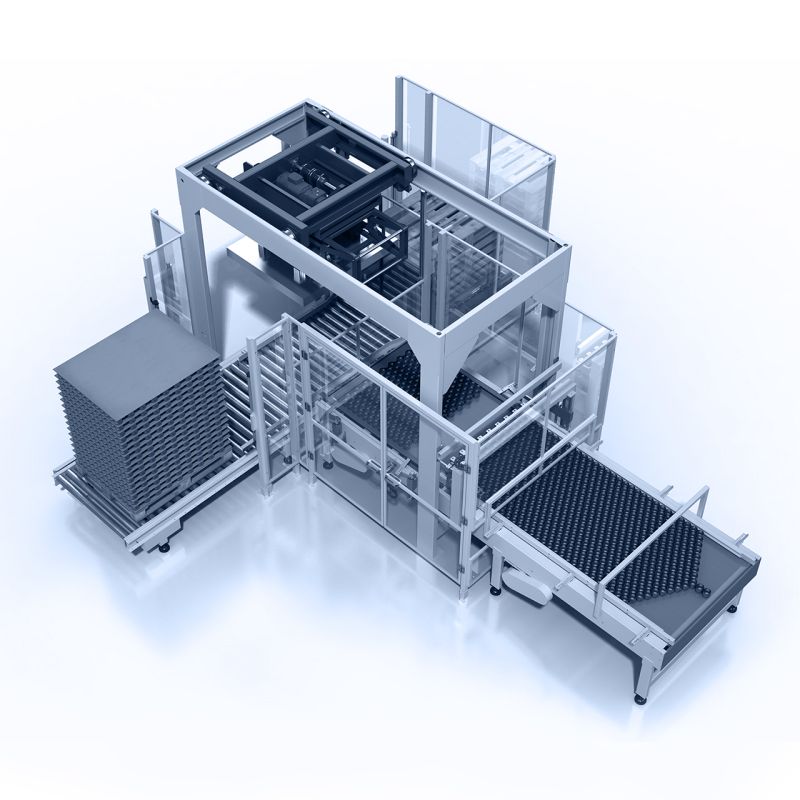

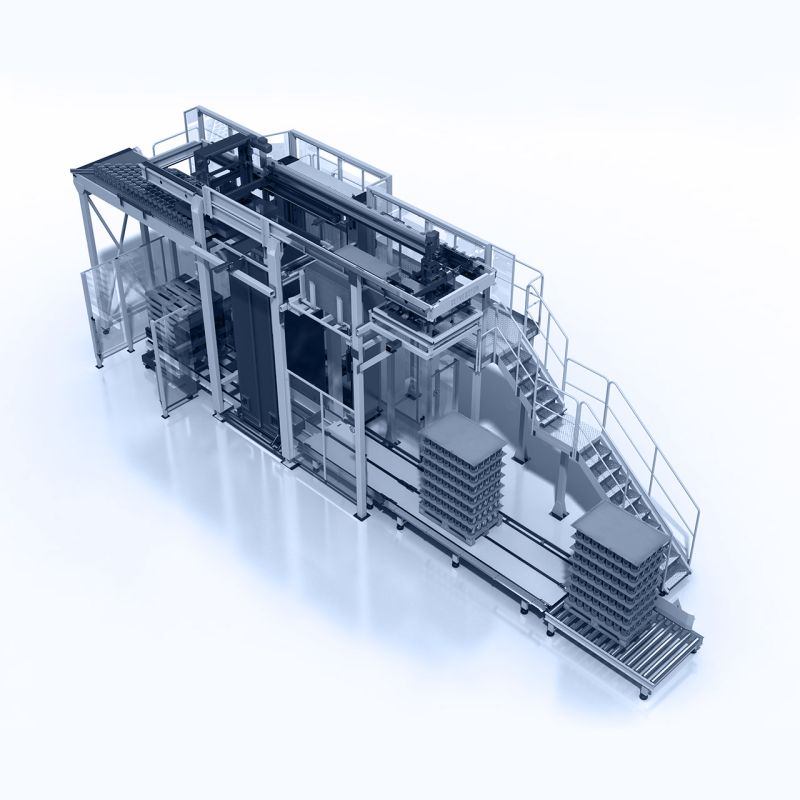

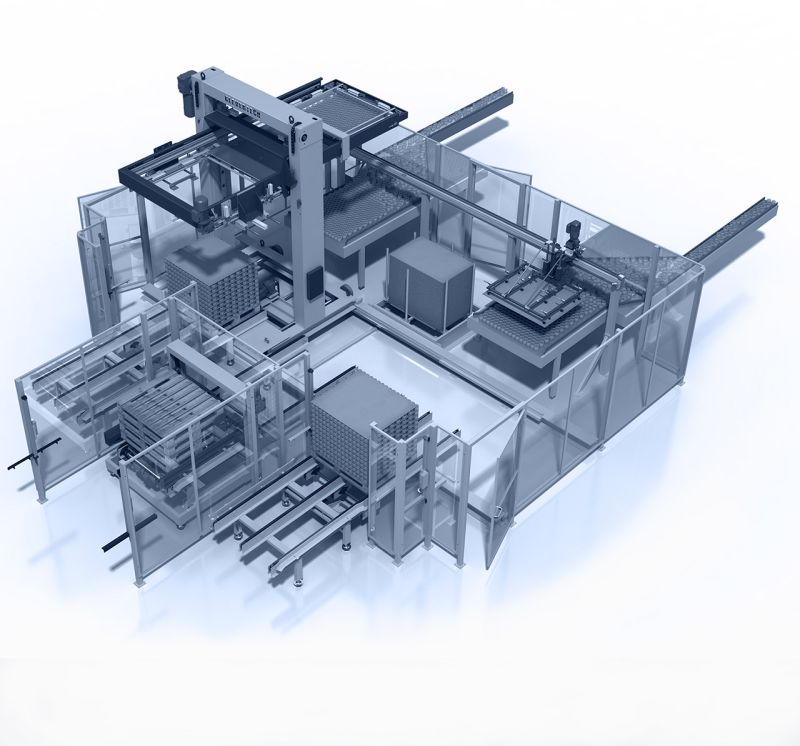

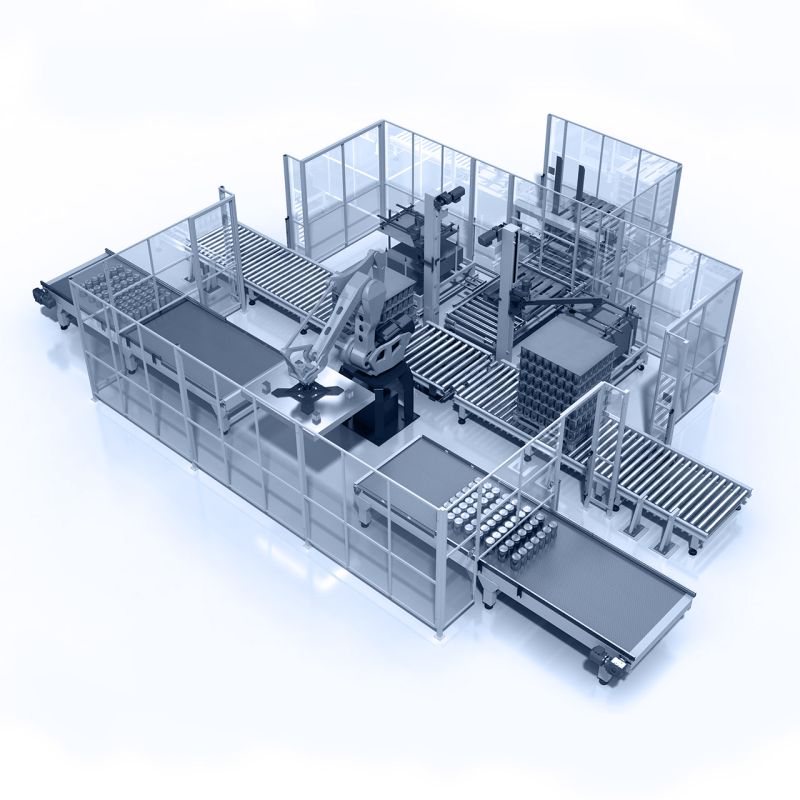

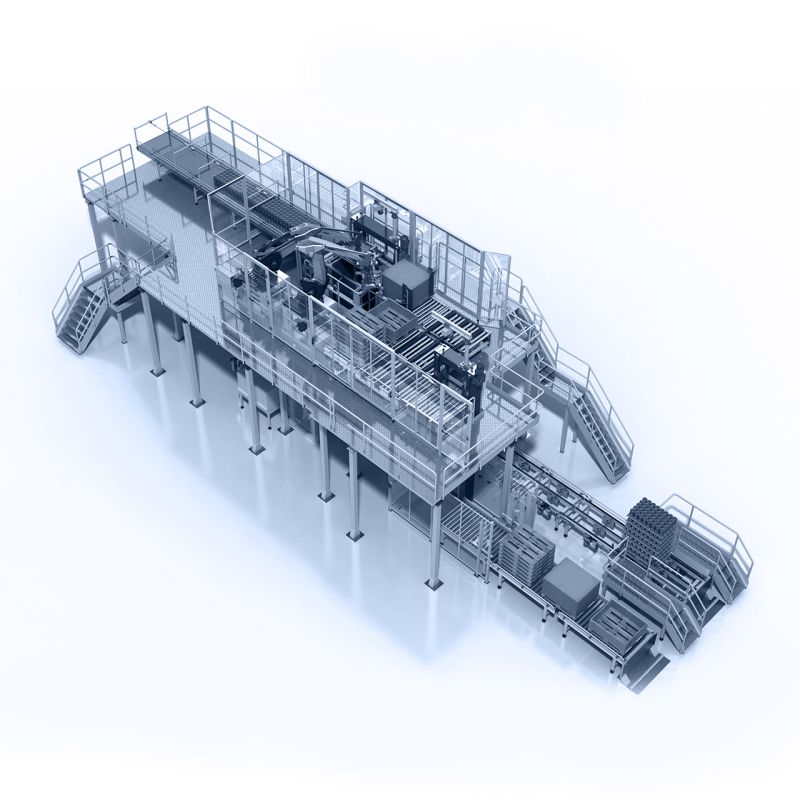

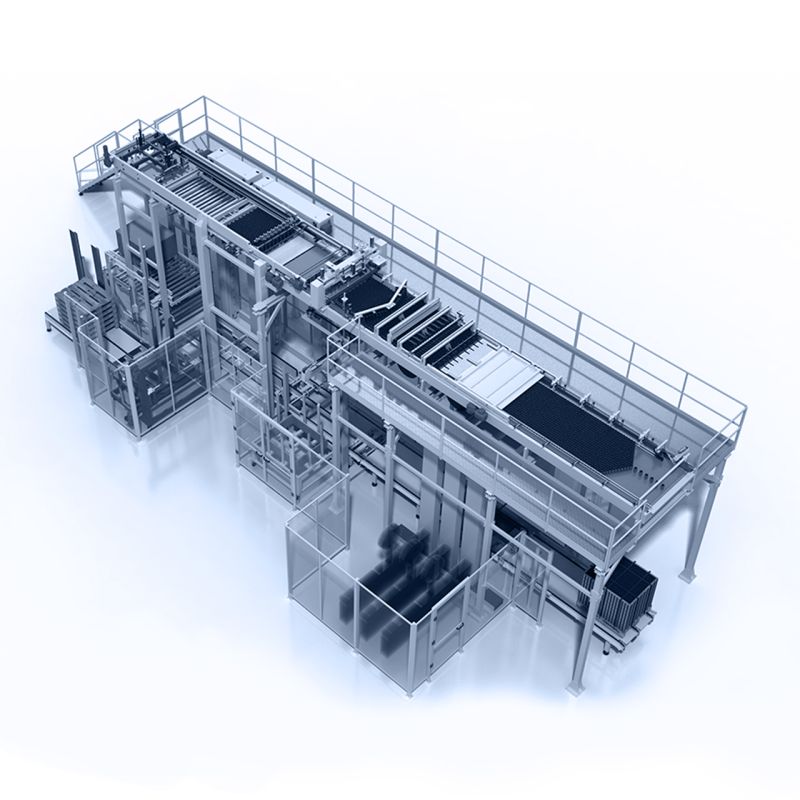

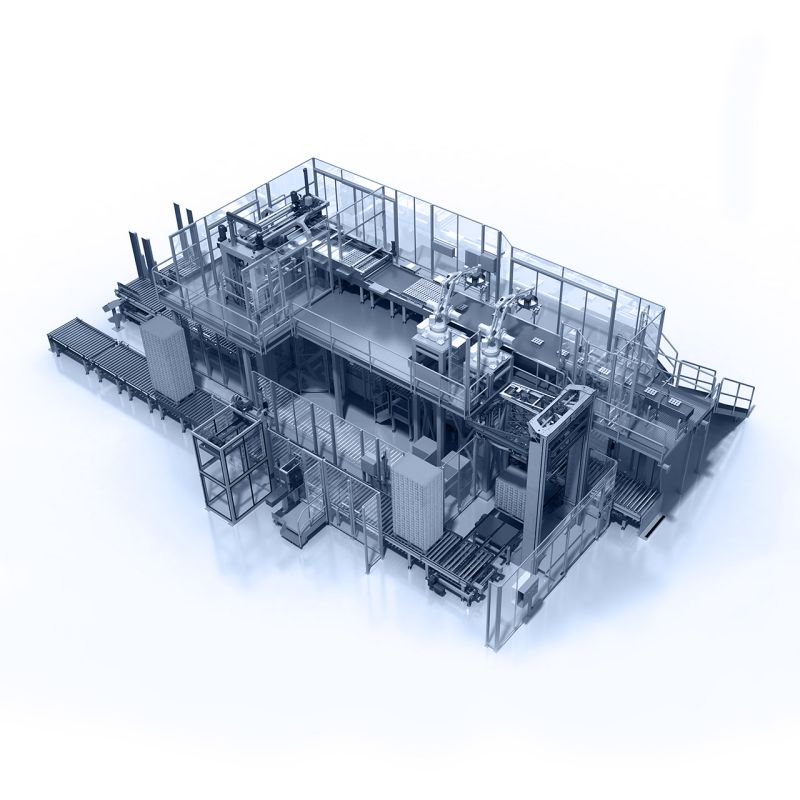

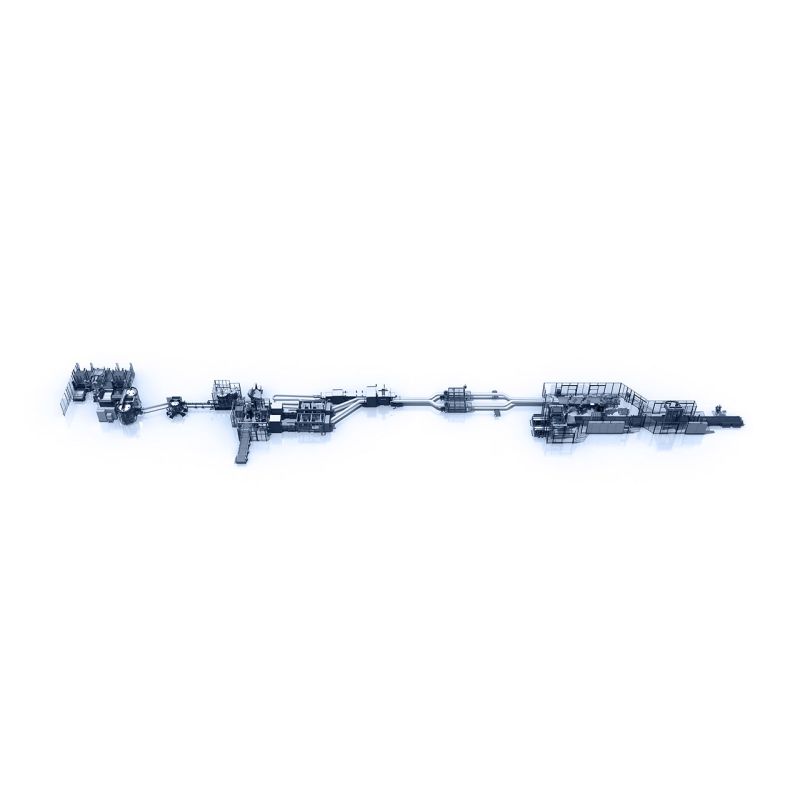

The solution achieved by Clevertech

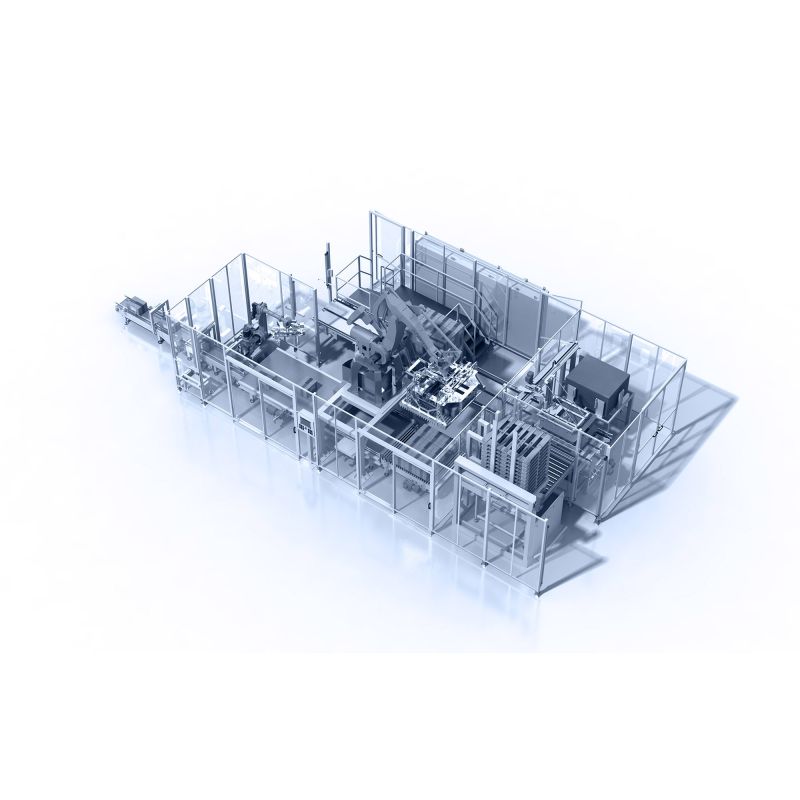

includes a depalletizing system high level outfeed with sweep off system and robotic system for layer pad – frame and slip sheet depalletizing and palletizing system high level infeed with robotic manipulators and a conveyor line. The Front and End of line developed is a suitable solution for high speed productions and suitable for space optimization. The solution is also particularly innovative since it has been designed and achieved pneumatic free in order to reduce compressed air consumption. The replacement of cylinders with motors reduces the TCO costs and maintenance cost significantly. This type of approach has long life of components and easier maintenance.

In particular, the solution designed by Clevertech has been appreciated in because of high level of customization.

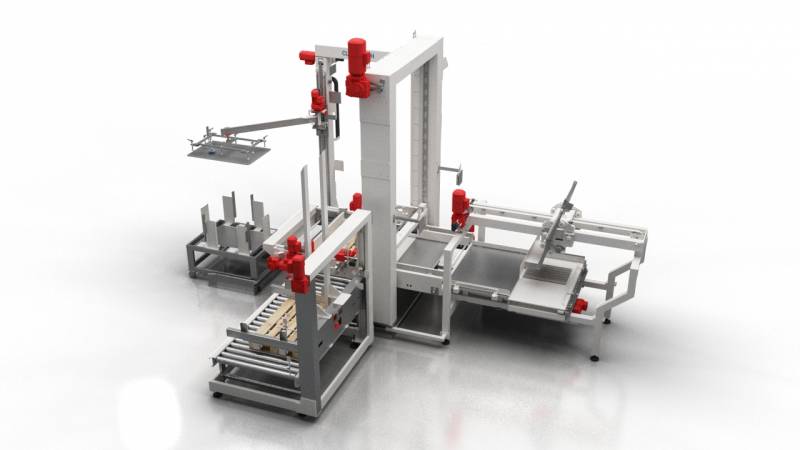

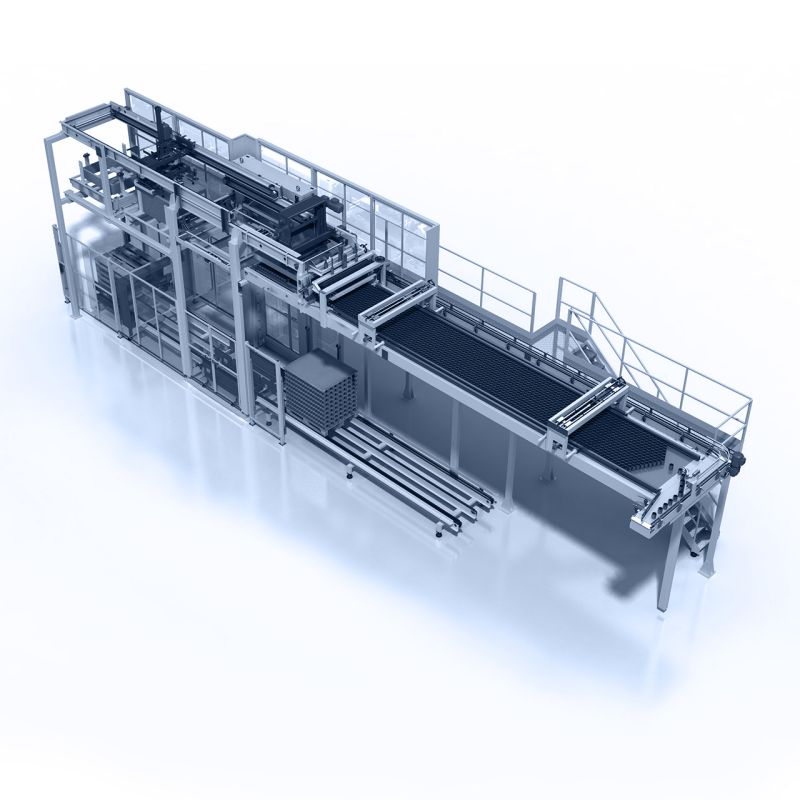

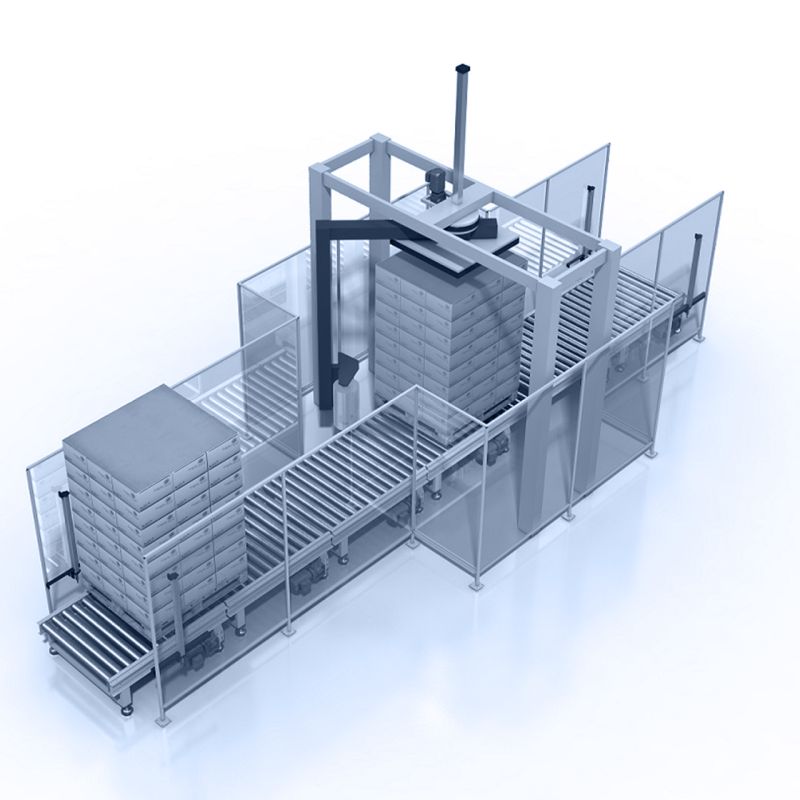

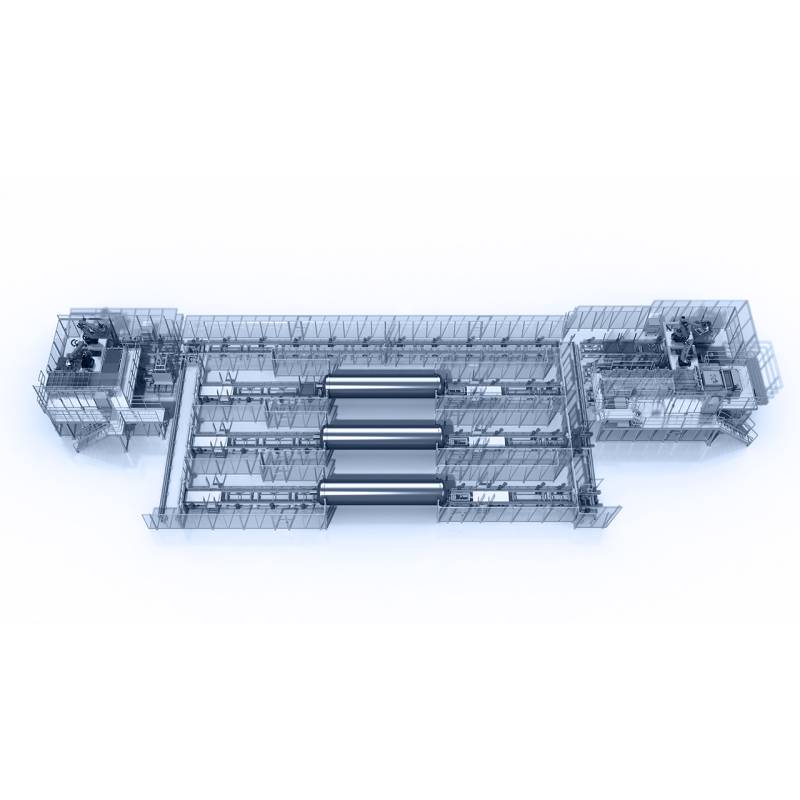

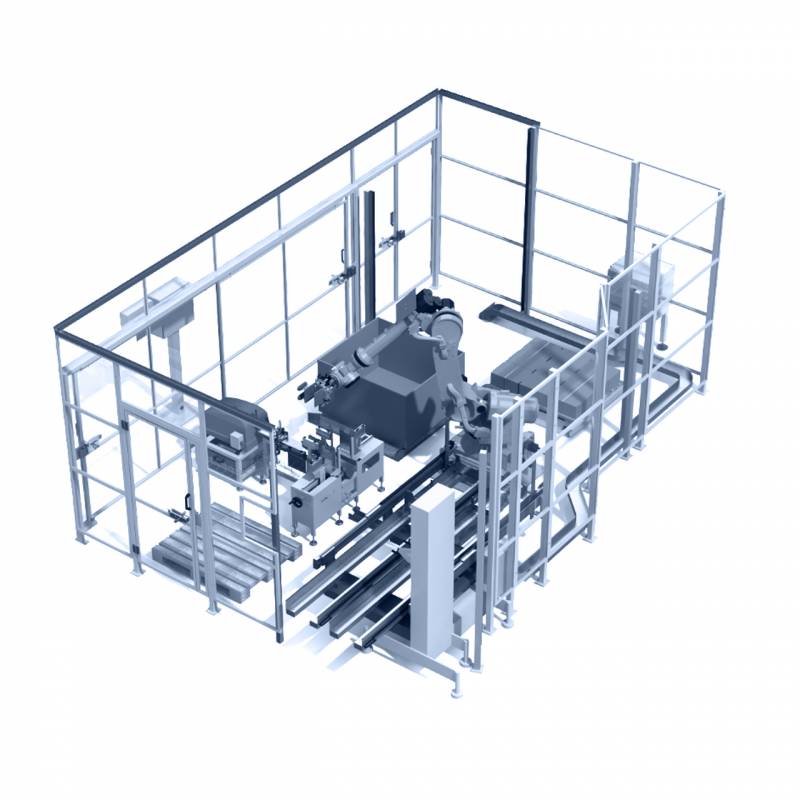

- Pallet conveyor line: Pallet conveyor with positive constant handling, side over posed-parallel chain conveyor and ultrasonic sensor for pallet presence reading

- Clean design approach: in order to facilitate the cleaning process. Mechanical and electrical design are specifically studied to avoid dust deposit

- Safety: great attention to details. For example, a specific safety barrier is positioned at the pallet elevation area

- Mechanical design: designed using TPM approach for easier maintenance

- Full pallet to depalletizing area: decoupling of 2 lines pallet infeed, with single file pallet feeding conveyor. Discharge pallet conveyor for quick product change over

The system is composed of:

- Infeed area with glue application system;

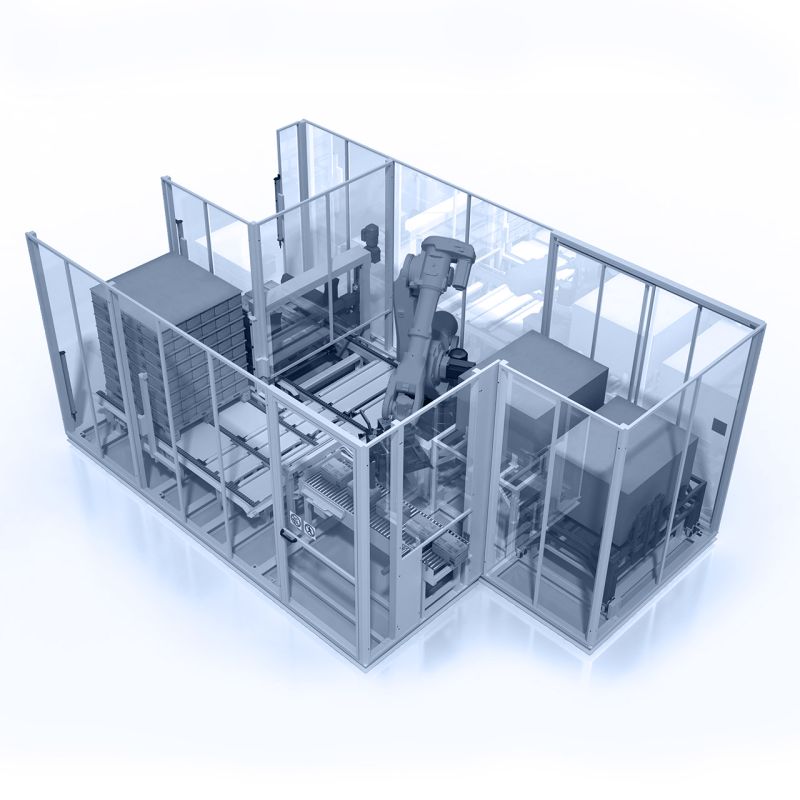

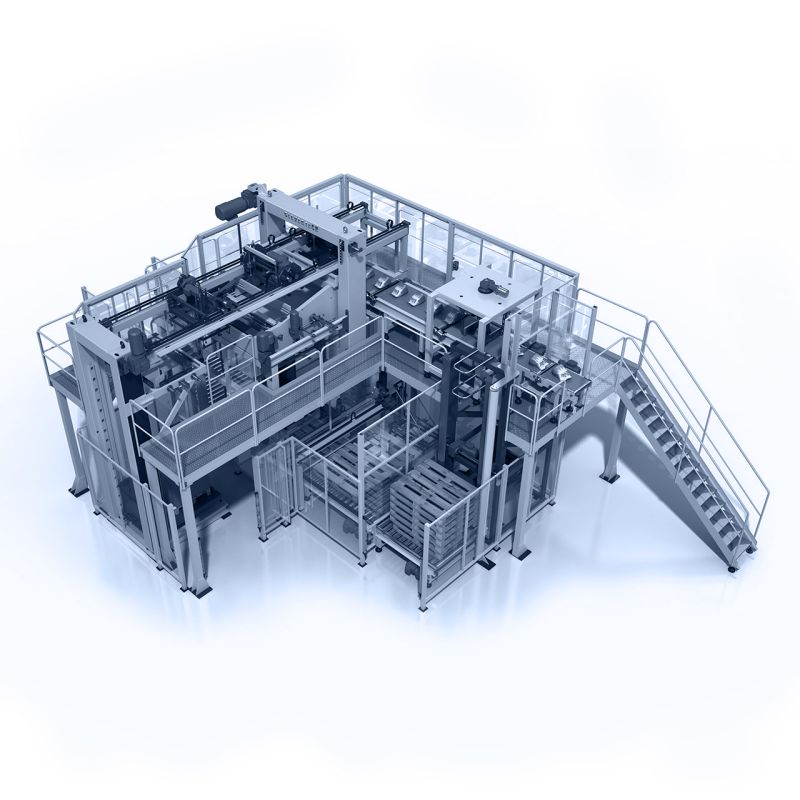

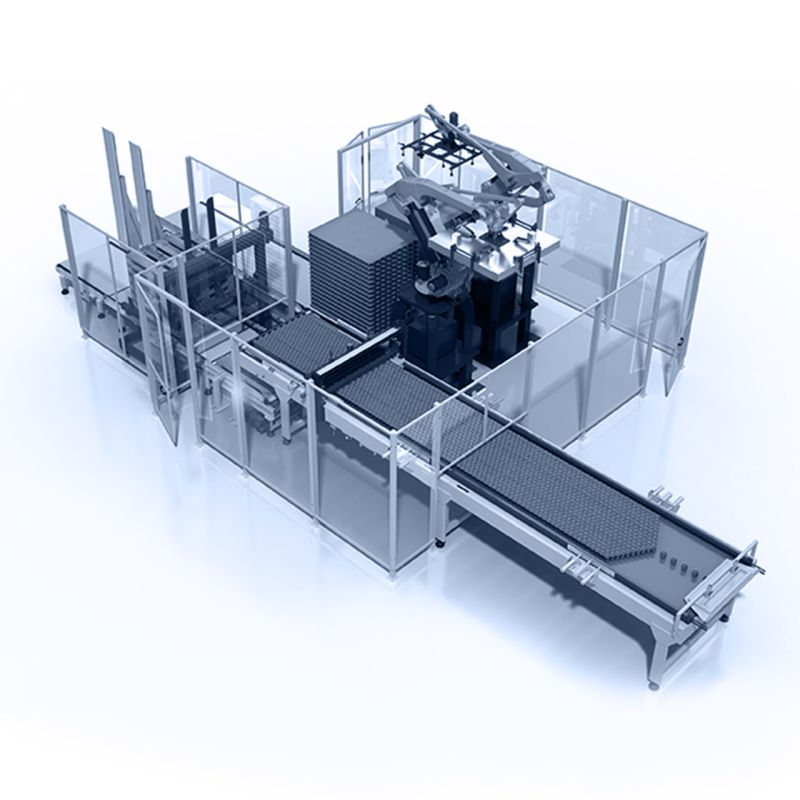

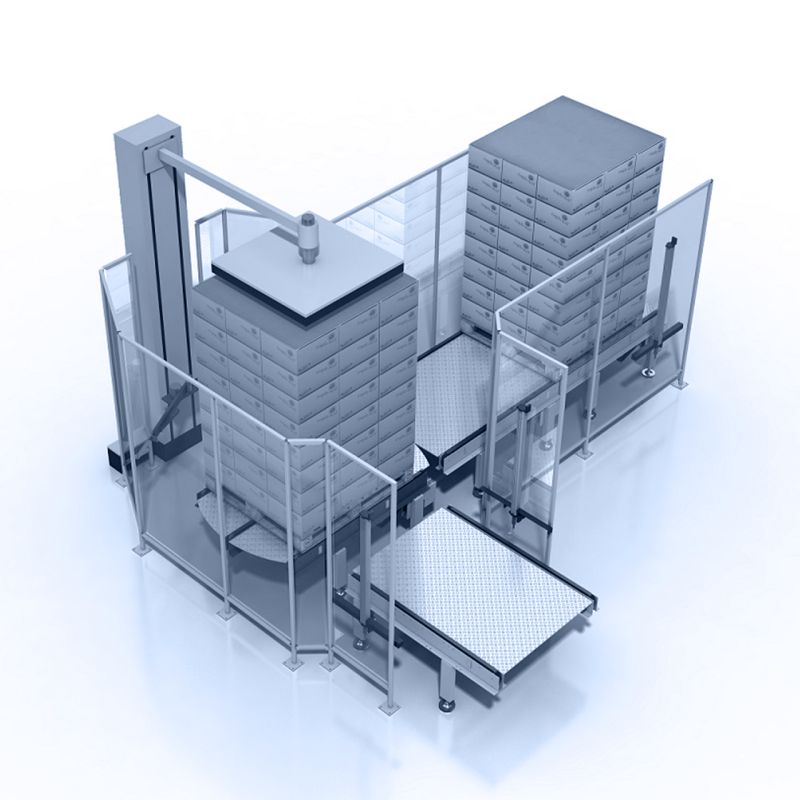

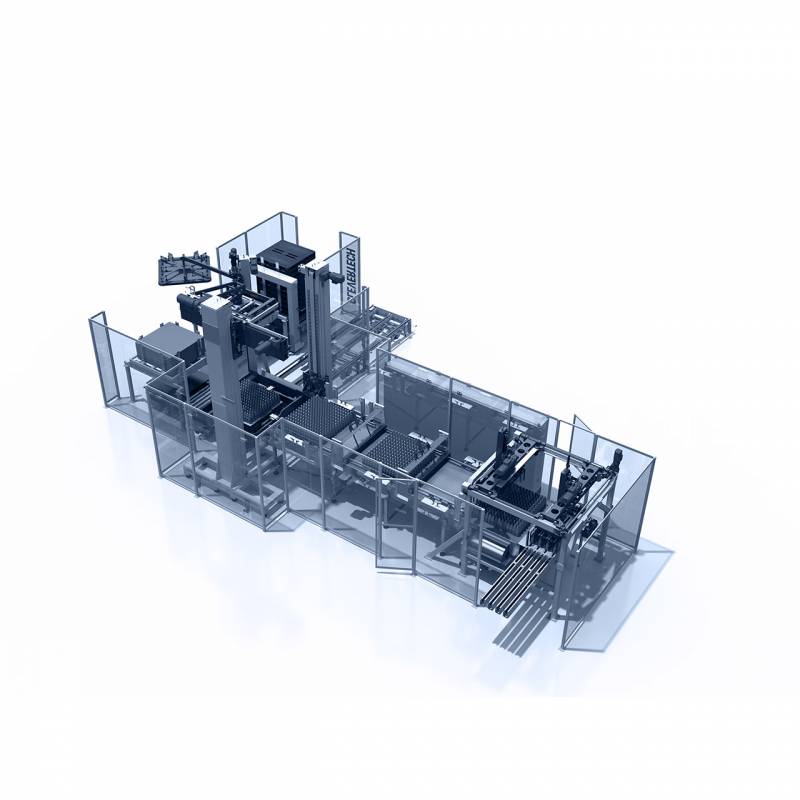

- Depalletizing system Mod. Hybrid – Fast Transfer high level outfeed with sweep off system for the layer and consumer products (interlayer pad – empty pallets and top frames) depalletized using a robotic system.

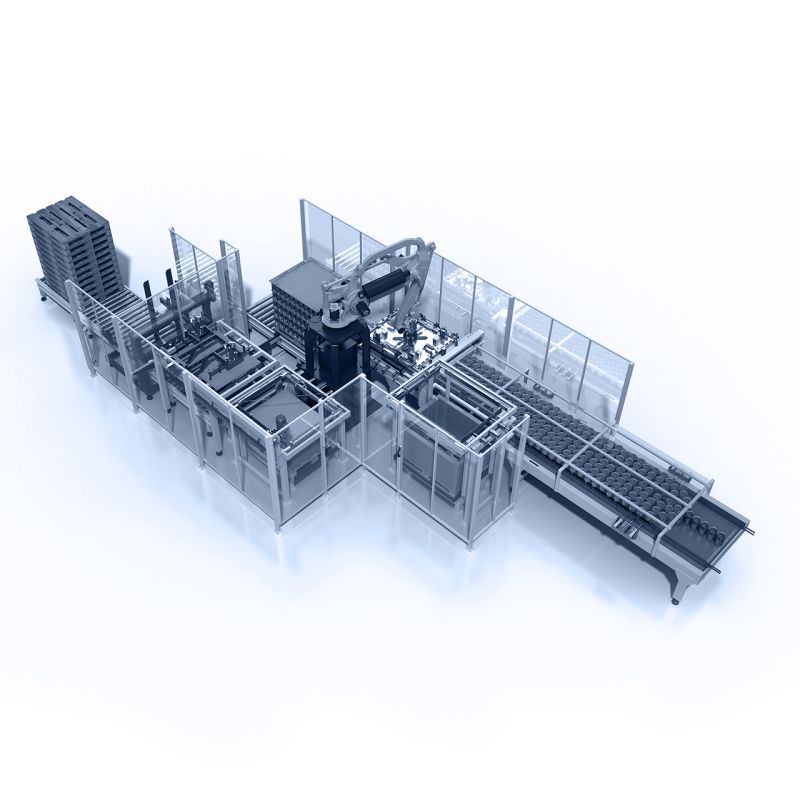

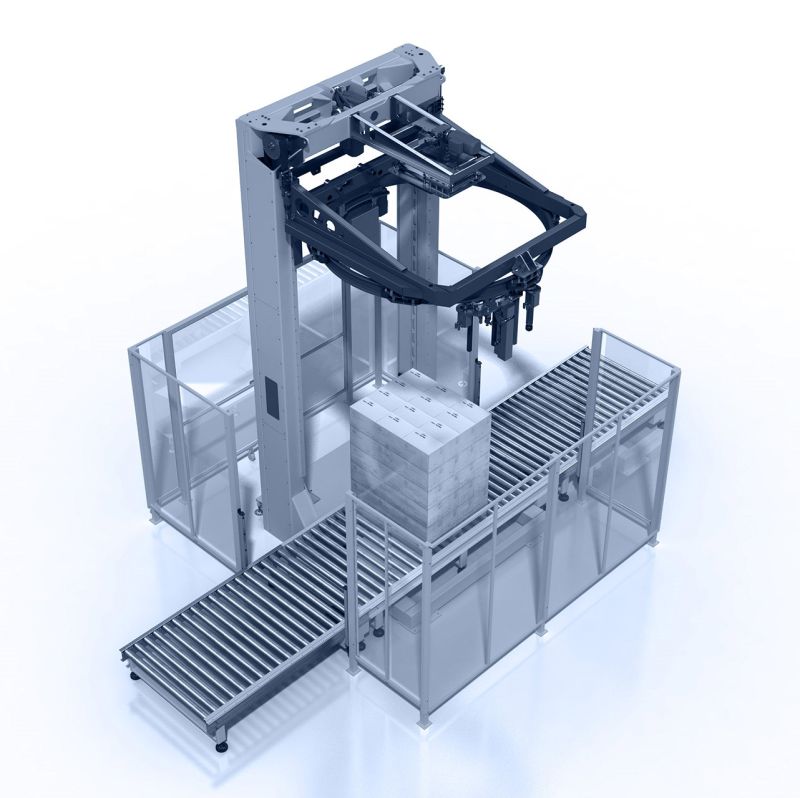

- Palletizing system Mod. Rocket, high level infeed with robotic manipulators for the cases

- Preforming area servo-motorized: the robotic manipulators in the preforming area has been specifically positioned for high speed requirements.

- The robotic arm does not interfere with palletized product and the robotic flaps is self-adjustable in order to adapt for different product formats.

- Pallet conveyor line

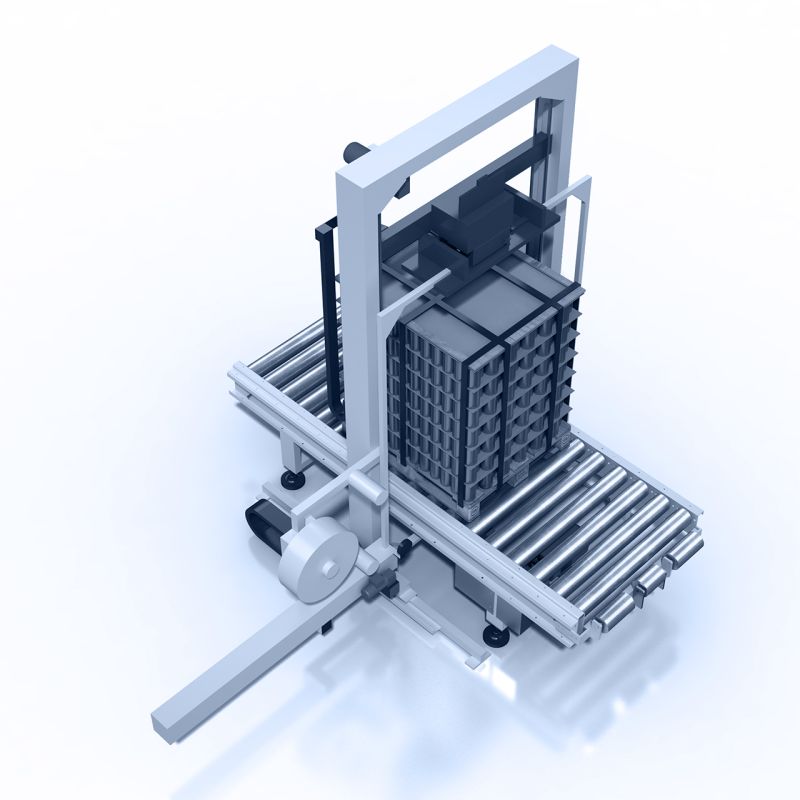

- Stretch wrapping machine Mod.PF80 with automatic lateral coil change-over.

Together with the Front & End of line, Clevertech added a Digital package which includes a digital spare parts catalogue and documentation. Using the application is possible to send a request for the offer of required spare parts. The digital package includes also, in case of machine stoppage, a specific guide with trouble shooting directly on PV in order to fix any possible problem. It is possible to reach a higher level of diagnostics with software implementation thus detect precisely the single components which is causing an issue and where we need the intervention.

Performance:

Depalletization:

8 layers/min

Pallettization:

9 layers/min

Efficiency: 99%

INFORMATION REQUEST

FOR THE PRODUCT

Food

MORE PRODUCTS